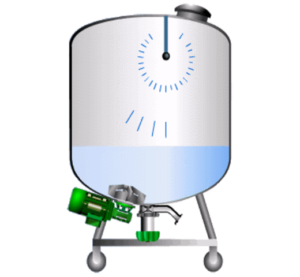

The bottom-mounted design means no mechanical lifting device is required. The risk of leakage is eliminated due to NovAseptic’s magnetic drive. Tank integrity is maintained as no shaft is led through the tank wall. Easy to clean and sterilize in place (CIP/SIP).

Shear seems like a simple enough concept to most people until they’re asked to define it. Related to liquids, shear is defined as relative motion between adjacent layers of a moving liquid. Some of the simplest examples include spreading butter on bread or applying sunscreen. In each case one level of the liquid (butter on the knife) is moving relative to the adjacent layer (butter on the bread). By also considering the velocity of this relative motion, we can calculate the shear rate. Shear rate is defined as the measure of the extent or rate of relative motion between adjacent layers of a moving liquid. Therefore: Shear Rate = Velocity / Distance.

Shear sensitive liquids can behave very differently when sheared. Some require shear to get them to the ideal viscosity for transfer or application. Others can be temporarily or irrevocably damaged by shear. It’s important to discuss the liquid’s nature with the manufacturer or to have a rheology test performed to determine how the liquid behaves when sheared over time. As soon as the liquid enters the vessel and enters the suction piping, it begins to shear as the liquid travelling through the middle of the pipe moves in relation to the pipe walls. The pump imparts shear as well between the rotating pumping elements and the stationary casing. Calculating these shear rates is possible using the equation above and considering the flow rate, pipe diameters, pump rotational speed, and internal pump dimensions. Combined with the liquid’s rheology data, this can help to make an educated decision regarding mixer selection and sizing.

Pump capacity is a term used to describe the maximum flow rate through a pump/mixer at its designed conditions. It is a measurement usually given in gallons per minute (gpm) or cubic meters per hour (m3/h).

GMP stands for Good Manufacturing Practice

Newtonian liquids are those that hold their viscosity regardless of shear rate. Consider stirring a glass of water; no matter how fast you stir, the water retains its viscosity. Conversely, non-Newtonian liquids change in viscosity depending on the shear rate. Paint for example is shear thinning, decreasing in viscosity as it is stirred. A corn starch and water mixture (sometimes referred to as oobleck) is shear thickening, literally allowing someone to run across the liquid’s surface, but sink in slowly if they remain stationary.

Call us in Ireland at +353 21 4510900 or UK at+44 1633 877505 or message us via our online form or web chat.