A Solution for Fluid Flow Processes

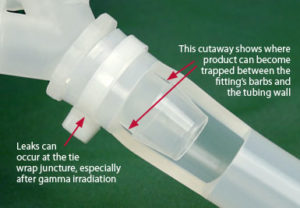

It’s a fact: Single-Use tubing sets can leak. And leaks contribute to all sorts of problems, from valuable product spilled onto the cleanroom floor, to safety hazards, to rework and added expense.

It’s a fact: Single-Use tubing sets can leak. And leaks contribute to all sorts of problems, from valuable product spilled onto the cleanroom floor, to safety hazards, to rework and added expense.

Tubing sets run the risk of entrapment as well. Fluids and organisms like bacteria can become trapped between the fitting’s barbs and the interior tubing wall, leading to potential contamination . . . and contamination can ruin an entire batch.

But there’s a solution: Molded manifold connections

Molded connections remove the risk of leaks and entrapment. By combining pre-made tubing with liquid injection molded material like silicone, fittings such as Y’s, T’s, crosses, reducers and Tri-Clamp® styles are molded directly to the tubing, eliminating gaps prone to entrapment.

With molded assemblies there’s much less need for expensive sterile connectors and therefore fewer cable ties needed for fitting-to-tubing attachment. There’s no need to use two ties to ensure a proper fit, and no need to hope that those ties are tight enough.

Don’t trust a batch of product worth millions to a $2 connection prone to leaks and entrapment.

Molded manifold connections and tubing assemblies:

- Simplify customer inventories

- Greatly reduce assembly time and costs – products arrive gamma irradiated and ready to use

- Increase safety – no cable ties means no sharp edges that can compromise bags used in the process flow

For further information please contact Emma Duffy on Ireland : +353 21 4510900 or fill out our enquiry form. For Benelux contact +31 85 0499770 or mail: Rob Mijnsbergen