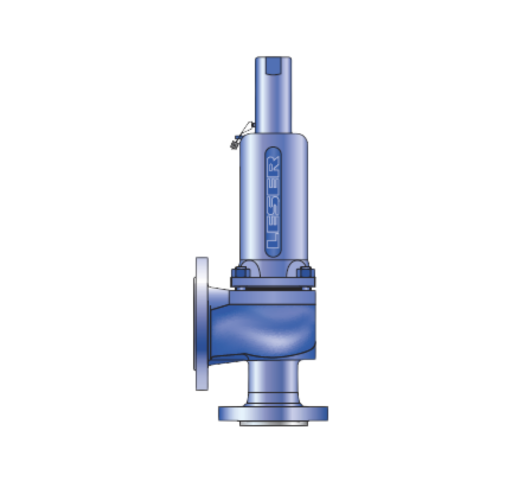

Product

LESER High Performance Flanged Safety Relief Valves

Designed for critical industrial applications, LESER’s High Performance Safety Valves deliver rapid, high-capacity relief. Optimised for vapor and gas systems, these valves achieve full lift at a mere 5% overpressure, ensuring swift discharge of maximum mass flow. They offer exceptional price-performance, adaptable configurations, and industry-leading blowdown control (-10% gas/steam, -20% liquid). Developed in collaboration with plant engineers, these top-selling spring-loaded valves prioritize process and equipment protection through efficient, reliable performance.