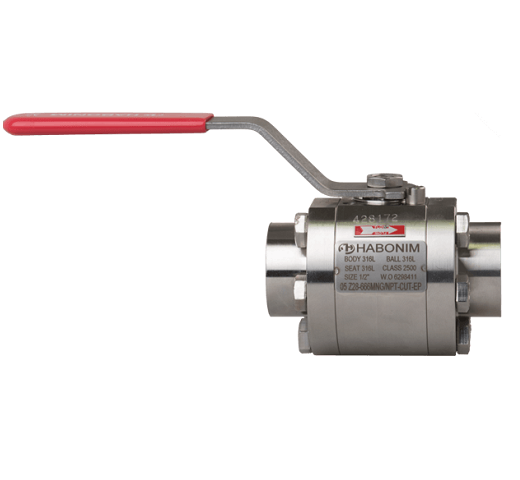

Technical Data

Design features up to 650 °C / 1200 °F

Basic design

Temperature range -60 °C to +400 °C (-76 °F to +752 °F)

Surface treatment LTPN

Materials Stainless steel A351 CF8M/CF3M, A479 316/316L, Carbon steel A216 WCB, A105, A350 LF2

T design

Temperature range -60 °C to +538 °C (-76 °F to +1000 °F)

Coating HVOF Cr3C2 (Chromium Carbide), HVOF WC-Co (Tungsten Carbide) and Stellite

Materials Stainless steel A351 CF8M/CF3M, A479 316/316L, carbon steel A216 WCB, A105, A350 LF2

T design

Temperature range -60 °C to +650 °C (-76 °F to +1200 °F)

Coating HVOF Cr3C2 (Chromium Carbide)

Materials Stainless steel A479 321/321H, A182 F22

Operation

Lever or gear operated, pneumatic or electric actuated

Body

- Full port design

- Unidirectional

- High flow capacity and minimum turbulence

- Fire safe design to API 607 and ISO 10497

Ball and metal seats set

- Leak rate to EN12266-1 Rate B (factory tested) is achieved by accurate grinding and lapping processes

- Surface treatments and coatings available for superb corrosion and abrasion resistance

- Habonim’s unique surface treatment, LTPN (Low-Temperature Plasma carbo-Nitriding).

- Constant preload of ball/seats set obtained by Inconel 718 Belleville spring

- Low operating torque

Stem

- Blowout-proof design

- Solid one-piece

- Tight stem-to-ball engagement

- High torque durability

- Live loaded stem seal

Minimum thermal expansion

- One size up and shorter body bolts

- Additional spring washers

Tongue & groove labyrinth design

- Zero leakage into the atmosphere

- Full compression of encapsulated body seal

- Accurate alignment of all parts