Case Study – Solution for a difficult mill-discharge application

A Goulds XHD heavy-duty centrifugal slurry pump was recently test-proven for a customer in a harsh application

Plant: silver mining and processing facility, slurry pumps used for mill discharge service. The pump liners and impeller were wearing out in eight to ten weeks, requiring frequent parts replacement and reducing production.

Plant: silver mining and processing facility, slurry pumps used for mill discharge service. The pump liners and impeller were wearing out in eight to ten weeks, requiring frequent parts replacement and reducing production.

Application: the pumps on the secondary grinding circuit are critical to the proper operation of the plant because the cyclone overflow from the pump discharge is sent downstream for further processing. Reduced wear life and frequent rebuilds were decreasing uptime and resulting in lost profitability

The installed pump was replaced with a new 125 XHD pump with HC600 liners and impeller. The compact pedestal made it easier to install the pump in the current location with the use of an adaptor base to line up the pump suction flange with the piping. The customer opted to make the adaptor base in-house.

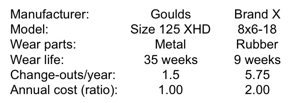

The previously installed pump components were wearing out at the following times:

- Liners: 1,400hrs (8.33 weeks)

- Impeller: 1,000hrs (5.95 weeks)

- Suction wear plate and shaft seal: 700hrs (4.17 weeks)

The customer desired to have a 50% increase in usable uptime from a replacement pump.

The Goulds XHD pump was installed and ran continuously ran for 5,760 hours (35 weeks) before being opened for inspection when very little parts wear was observed.

It was determined that the Goulds pump offered an increase of 400% in performance uptime

The XHD performance exceeded expectations and delivered real savings for the lowest cost of ownership:

The 125 XHD annual parts repair cost was half that of the existing rubber-lined pump. With labour and production downtime factored in, the total cost of ownership for the Goulds 125 XHD is less than one-third the cost of the competitor’s pump.

A compact pedestal became one of the great features designed into the XHD. Its purpose is to allow easy retrofit of the XHD to an existing slurry pump installation.

The compact pedestal allows for the use of an adaptor base so that the suction piping centreline can be matched without any foundation working having to be done.

Goulds have designed an adaptor base for the models SRL and 5500, along with bases for the most popular size and frame combinations of Weir’s model AH (Warman).

Features of the XHD Slurry Pump include:

Features of the XHD Slurry Pump include:

- The suction seal ring is adjustable while the pump is in operation allowing peak efficiency and performance to be maintained, along with extending wear life

- Split stuffing box and gland for quick and easy packing adjustment and replacement.

- Special tapered impeller thread to facilitate assembly and alignment

- Extra-thick, replaceable, hardened chrome-iron liners for extended wear life

- Patented i-AlertTM vibration and bearing temperature monitor

- Capacities to: 2,950 m3/h (13,000 GPM)

- Heads to: 85 m (280 feet)

- Pressures to: 17 bar (250 PSIG)

- Temperatures to: 120°C (250°F)

Applications for the XHD include:

- Primary Metals: SAG/Ball Mill, Cyclone Feed, Tailings

- Mineral Processing: Slurry Transfer, Flotation Cells, Thickener Underflow

- Non-Metallic Mining: Heavy Media, Cyclone Feed, Raw Coal, Clay, Soda Ash and Phosphate Slurries, Slurry Heater, Slurry Digestion, Hydrate

- Power: Absorber Recycle, Gas Cooling, Filter Feed, Lime and Ash Slurries

- Sand & Aggregate: Sand Slurries, Tailings

If you have any queries or require further information, send us a product enquiry, or alternatively contact John Scott in Ireland at +353 21 4510900; or UK: +44 1633 877505.