Conventional positioners use linkage kits and therein lies the problem. Your multi-million process is ultimately controlled by a piece of steel.

Problems with Conventional Positioners

- Mechanical device – bellows and linkages

- Requires alignment / adjustment

- High hysterisis & deadband

- Difficult to calibrate

That’s even if it’s in its as-new state. However, the reality is they are knocked out of shape / broken or loose and that’s the item controlling the plant.

Linkage free positioners use a magnetic assembly that is non contact. What does that mean?:

- No mechanical arms to be broken or loosen

- Accurate feedback for improved control

- Easy to calibrate

- Easy to install – Namur mounting

- Compact in size which helps on small valves or in tight spaces

- On-board performance diagnostics

- Easy to use digital local interface with LCD display

- Can be configured to communicate via wireless for critical monitoring or reporting

How does that translate to benefits for my plant? Let’s look at a case study:

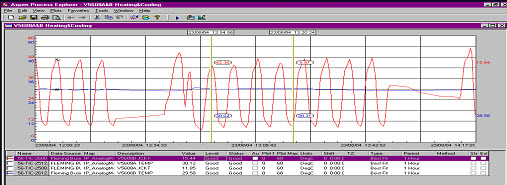

Reactor temperature control loop with poor control:

The jacket temperature is cycling between 10 and 45 degrees C over a period of 8 minutes to maintain a constant vessel-contents temperature of approx 30 C.

The jacket temperature is cycling between 10 and 45 degrees C over a period of 8 minutes to maintain a constant vessel-contents temperature of approx 30 C.

The hunting / cycling resulted in considerable steam and chiller electrical consuption for little or no overall heating or cooling input to the vessel contents.

Recommendation: the control system be investigated

Result: by fitting an Emerson Fisher DVC 2000 the control loop performance can be considerably improved with a resulting 24k saving in electrical consumption.

Should you be interested in improving your control loop then why not send us a product enquiry or contact UK: +44 1633 877505 or Ireland: +353 21 4510900.