For those critical applications where you need to ensure you have a high performance butterfly valve that is FIT FOR PURPOSE, it is worth reviewing the design features that will ensure long and trouble free valve service.

The Double Eccentric construction offers advantages in applications with high pressure and temperature loads:

The Double Eccentric construction offers advantages in applications with high pressure and temperature loads:

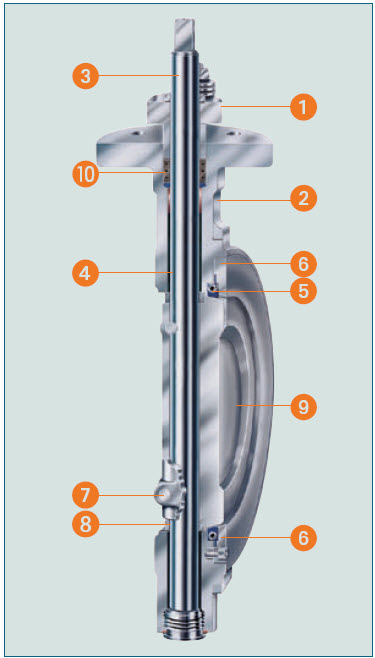

- Top flange that conforms to EN / ISO 5211.

- Mono-bloc body with over-running safety device.

- Straight-through shaft for maximum flex rigidity.

- The shaft should be carried in maintenance free, excess length, corrosion proof and temperature stable bearings. This ensures exact positioning of the valve disc.

- Spring supported PTFE seat ring guarantees absolute tightness and compensates for wear. Replacement of the seal ring without dismantling shaft and valve disc.

- Clamping ring protects seat ring from abrasion and erosion.

- Fit and proper connection between disc and shaft by means of tangentially arranged taper pins.

- Hardened bearing rings for exact centering of the valve disc.

- Valve disc located in double eccentric bearings results in low torque and reduces wear. All finishes are mechanically micro-finished.

- Self re-adjusting shaft seal.

ESI Technologies in partnership with EBRO have many years experience in the butterfly valve industry. Please contact Brian Foley at ESI if you require more detailed information on how to specify and select the best high performance butterfly valve for your application.