Avoiding Pump Cavitation Problems, if the checklist below does not solve your problem, a low NPSH pump like a Discflo may be the solution:

The available NPSH of the system must be equal to or greater than the NPSH required in order to avoid pump cavitation difficulties. In most cases, cavitation may either be avoided or corrected by any one or combination of the following practices

Keep available NPSH as high as possible by:

- Keeping the maximum available suction head on the impeller eye

- Keeping the liquid temperature as low as possible

- Keeping the suction pipe size as large as economics will allow

- Avoiding any unnecessary elbows or other fittings and valves on the suction line to keep suction line losses as low as possible

- Selecting the pump which gives the most favourable NPSH requirements within the bounds of the economy

- Specifying the pump discharge head as near as possible to actual operating conditions, the most common cause of cavitation in pump installations is pump discharge requirements specified for above the actual requirements of the installation. From the performance curve data, it’s obvious that the tendency toward cavitation increases as the pump head drops or as the capacity increases.

Keep the pump discharge head as near the specified head as possible and correct systems which are at fault in this respect by:

- Throttling discharge gate or other valves until pump cavitation noise disappears

- Installing orifice or venturi in the discharge line

- Cutting pump impeller to a predetermined smaller diameter

- Reducing pump speed if possible and where practical

- Decreasing discharge pipe size if practical

Where increasing the discharge head will not correct the trouble.

- Lower pump nearer to water level where lifts occur if possible

- Lower pump or raise water level if possible where suction head occurs

- Increase suction pipe size and remove any unnecessary elbows, other fittings and valves, even if suction lines and pump have to be reoriented. These three practices may involve considerable additional expense.

Other alternatives to solve Pump Cavitation would be to:

Other alternatives to solve Pump Cavitation would be to:

- Use a pump of a larger size and run it at a lower speed because the required suction head would then be reduced. This involves a larger initial investment and may increase operating costs if the large unit has lower efficiency.

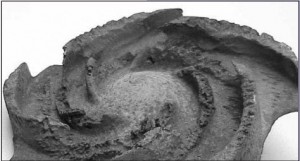

Use a pump with Low NPSHr, here the Discflo Pump is worth considering as it has an NPSHr of approx a third of conventional centrifugal pumps

To speak to an engineer about pump problems like cavitation contact ESI on either UK +44 1633 877505 or Ire: +353 21 4510900 or by using the enquiry form

At ESI Tech, we provide a wide range of pumps including magdrive pumps, centrifugal pumps, vacuum pumps, single use pumps and sanitary pumps among others. Contact us for free expert advice today.