Boost Your Process Efficiency & Sustainability

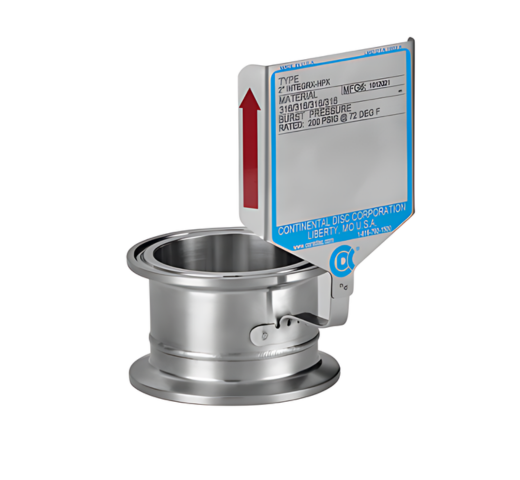

with INTEGRX-HPX™ Sanitary Rupture Discs

There is several sustainability benefits associated with using rupture discs from the Continental Disc Corporation (CDC), particularly the INTEGRX-HPX™ Sanitary Rupture Disc. These benefits contribute to both environmental sustainability and process efficiency, which are increasingly critical in industries such as biopharmaceuticals. Here are some key sustainability advantages:

Reduced Waste Through Long Service Life

The INTEGRX-HPX™ rupture disc is designed for optimal performance and longevity. By manufacturing and testing each disc to withstand specific conditions, CDC minimises the frequency of replacements. This longer service life reduces the need for frequent disc changes, lowering waste from discarded materials.

Minimised Risk of Installation Damage

The innovative design of the INTEGRX-HPX™ reduces the likelihood of installation-related damage, which can lead to premature failure and unnecessary waste. By ensuring easy and reliable installation, these rupture discs help prevent unnecessary material consumption and waste generation, contributing to more sustainable operations.

Sanitary Design Reducing Resource Use in Maintenance

With a crevice-free design that complies with ASME BPE standards, the INTEGRX-HPX™ rupture disc requires less intensive cleaning and maintenance. The cleanability features, such as being CIP (clean-in-place) and SIP (sterilize-in-place) compliant, help reduce harsh chemicals, water, and energy during cleaning processes. This lowers the environmental footprint of maintenance operations.

Efficient Process Control and Reduced Downtime

The INTEGRX-HPX™ improves overall process efficiency by ensuring safe and reliable pressure relief, minimising unplanned downtime due to over-pressurisation incidents. Reduced downtime and optimised processes lead to less energy consumption, fewer raw material losses, and a lower overall environmental impact.

Compliance with Global Standards

The INTEGRX-HPX™ rupture disc meets globally recognised standards such as ASME BPE for cleanability and sterility. By complying with these stringent standards, CDC rupture discs help reduce environmental contamination risks, ensuring that production processes meet sustainable manufacturing practices. For industries like biopharmaceuticals, this compliance promotes more sustainable, cleaner production processes.

Efficient Material Usage

CDC allows customers to control the type and source of seal materials used, providing an opportunity to select more environmentally friendly options. This flexibility supports sustainability initiatives by enabling the use of materials that may be recyclable or sourced through eco-friendly suppliers, without compromising the rupture disc’s performance.

Optimised for Specific Applications

Each INTEGRX-HPX™ rupture disc is customised for the application, whether for gas/vapour or liquid processes. This tailored approach ensures the disc performs optimally, preventing failures and reducing the frequency of replacements. Properly matched rupture discs for specific process conditions lead to more efficient use of materials and energy, contributing to resource conservation.

Local and Global Certifications

With approvals like PED (CE), UKCA, and CRN, the INTEGRX-HPX™ rupture disc aligns with global sustainability goals, as these certifications often include requirements for energy-efficient and environmentally conscious manufacturing practices. Continental Disc maintains a system for tracing products back to Conflict Free Smelters in compliance with the Dodd Frank Act – Section 1502 and documents that all purchased materials are from non-conflict sources. Click here for more information

Conclusion

By enhancing operational efficiency, reducing waste, and minimising the environmental impact of maintenance and cleaning processes, Continental Disc Corporation’s rupture discs offer clear sustainability benefits. The INTEGRX-HPX™ Sanitary Rupture Disc, in particular, supports biopharmaceutical manufacturers in meeting stringent environmental standards while maintaining high performance and safety. Discover our full range of bursting discs now.

Integrating rupture discs like the INTEGRX-HPX™ into industrial processes can help companies achieve their sustainability objectives, promoting cleaner, more efficient, and less resource-intensive operations. Contact ESI today to discuss your specific requirements, use our contact form or webchat.