Technical Data

The process is a gas-phase process therefore both internal and external surfaces of complex parts such as valves, fittings, process equipment and instrumentation can be processed.

As a result stainless steel parts, once treated, gain the superb corrosion resistance of tantalum and maintain the mechanical properties of steel at prices competitive to speciality alloys such as titanium, nickel alloys (Hastelloy C276, C22, B2) and zirconium.

Possible materials

The most common materials to be treated are 304 and 316 stainless steel, however, other iron-based substrates are possible in the process. These substrates include alloys based on copper, chromium, cobalt and ceramics. Titanium and nickel alloys may be suitable in the process but it will depend on the grade of the material selected. Finally, polymers and other low-temperature materials are not possible to treat due to the high-temperature process.

Substrate suitability:

Suitable:

- Metals and alloys based on iron, cobalt, chromium and copper

- Stainless steel and CoCr (alloys)

- Most metal oxide ceramics

Possible:

- Certain types of titanium and nickel-based alloys are more difficult to handle but may be possible

- Please consult us

Not possible:

- Substrates with melting points below 800C / 1,450F

- Zinc and zinc containing alloys

Geometry and size:

Standard set-up

- Parts of a dimension up to 425 dia x 700mm height (17.5 x 27.5″) would be considered standard-sized parts

- Depending on the geometry of the part, sizes up to 450 dia. x 850mm height (17.7 x 33.5″) may also be treated

Large parts set-up

- Larger parts up to several meters long and wide can be processed

- Please contact us for details

Utilising standard-sized components as base parts:

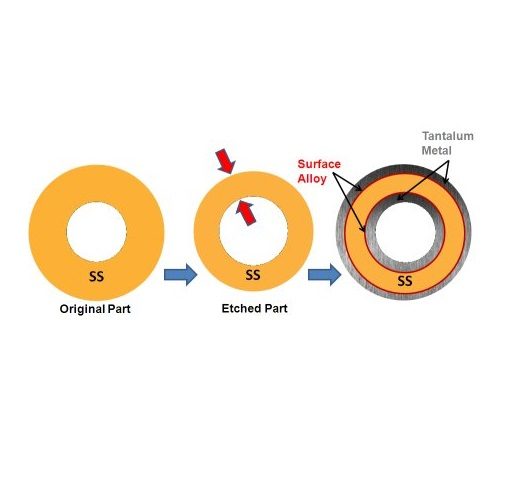

Part of what makes the Tantaline process unique is the ability to utilise standard off-the-shelf products from various manufacturers and maintain the original dimensions and tolerances of those parts

This is achieved by first removing 0.002” or 50 microns of stainless steel by machining and/or by using an etching process. By removing 0.002″ or 50 microns of material before applying a similar tantalum metal it is possible to maintain the net shape and dimensions of the part

Initial machining/etching will add costs to the overall process, but offers the advantage of short lead times, as the base parts can be sourced from stock instead of being specially made

Tantaline treatment:

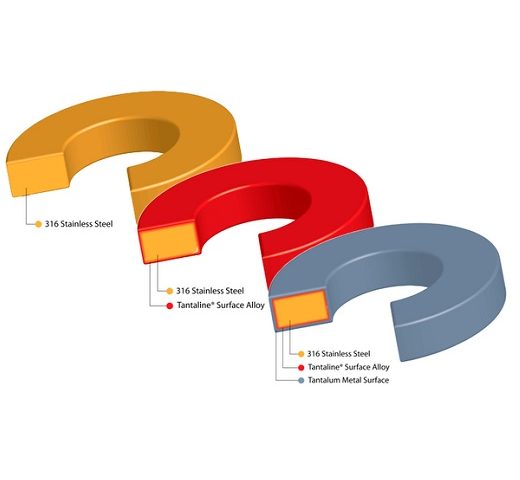

The surface alloy is what makes tantaline extremely rugged and durable:

- During the Tantaline process a furnace is heated to a temperature between 700 – 900C where tantalum metal is chemically reacted and vaporised

- At this high temperature, conditions suitable for solid-state diffusion and alloy bonding at an atomic level are possible. This is important because it virtually eliminates the risk of chipping, spalling and delamination that may be seen with traditional coating processes

- Next, because it is a gas-phase process, both internal and external surfaces can easily be treated making the Tantaline process geometry independent and capable of treating complex products

- Finally the tantalum surface that is grown is 100% dense, ductile and has low tension. This is very different from thermal sprays since the Tantaline process occurs at an atomic level, creates a surface alloy, and is geometry-independent

Post treatments:

The surface finish required for your product could be achieved by post-treatment polishing & grinding. Depending on the criteria of the customer, there are a variety of polishing and grinding techniques that could be used to meet even the strictest specifications. From vibration polishing to tolerance grinding, where excess layers of tantalum are machined off, there is a solution for most customers’ needs

- Vibration polishing (standard)

- Fine grit grinding

- Bright polishing

- Tolerance grinding

Quality control:

- All parts are 100% inspected for the integrity of the surface by placing the parts in boiling 32% HCl acid for 48 hours

- The Tantaline treated products are guaranteed free from any defects and have the chemical properties of pure tantalum

Application

This quick guide covers most topics to consider before having items Tantaline treated. If in doubt, please contact us

Suitable media:

Tantaline is very suitable – no corrosion rate:

- At temperatures up to 150C (300F) Tantaline is immune to nearly all organic and inorganic compounds such as mineral acids, and has similar corrosion resistance to that of glass

Tantaline may be suitable – depending on specific conditions:

- Between 150 and 300C the specific media and concentrations need to be evaluated. Please consult us

Tantaline is not suitable for:

- Strong Bases PH>12

- Hydrofluoric Acid (HF)

- Fuming Sulphuric Acid

Tantaline layer thickness:

- Tantaline may be supplied with layer thicknesses between 10 and 200 micrometres (0.5 to 8 mils). For layer thicknesses higher than 200 micrometres (8 mils) tantalum cladding is probably more economical. Critical dimensions and tolerances are maintained on the original part through the etching process

- Standard Tantaline treatment is 50 micrometres (2 mils). Standard Tantaline treatment is most efficient for media with nil corrosion (see “Suitable media”)

- For media where slight corrosion of tantalum is expected (e.g. 25% HCl at temperatures above 190 °C or sulfuric acid 98% at temperatures above 175°C) Tantaline layers thicker than 50 micrometres (2 mils) are recommended

Suitable geometrics:

Standard set-up

- Parts of a dimension up to 425 dia x 700mm height (17.5 x 27.5″) would be considered standard-sized parts

- Depending on the geometry of the part, sizes up to 450 dia. x 850mm height (17.7 x 33.5″) may also be treated

Large parts set-up

- Larger parts up to several meters long and wide can be processed

- Please contact us for details

Suitable substrates:

If you have no preference we suggest AISI 304L or 316L Stainless

Substrate suitability:

Suitable

- Metals and alloys based on iron, cobalt, chromium and copper

- Stainless steel and CoCr (alloys)

- Most metal oxide ceramics

Possible

- Certain types of titanium and nickel-based alloys are more difficult to handle but may be possible

- Please consult us

Not possible

- Substrates with melting points below 800C / 1,450F

- Zinc and zinc containing alloys