Product

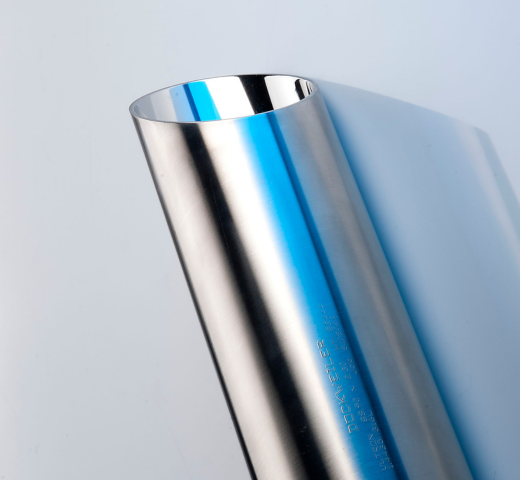

Dockweiler SS Tubes & Fittings

ESI Technologies Group is the trusted distributor of Dockweiler Stainless Steel Tubes and Fittings in Ireland, delivering industry-leading solutions for the semiconductor, pharmaceutical, and life sciences sectors. Engineered for exceptional surface quality and ultra-high purity, Dockweiler products meet the most stringent requirements for hygienic and high-tech applications.

Backed by comprehensive quality assurance and full traceability, Dockweiler tubes and fittings are certified to meet national and international industry standards, including ASME BPE (BPE-105, BPE-169). Whether for sterile processing, ultra-pure fluid transfer, or critical manufacturing environments, Dockweiler ensures uncompromising quality and compliance.

Contact ESI Technologies Group for premium-grade stainless steel tubing solutions that offer reliability, safety, and performance in your most demanding applications.