Product

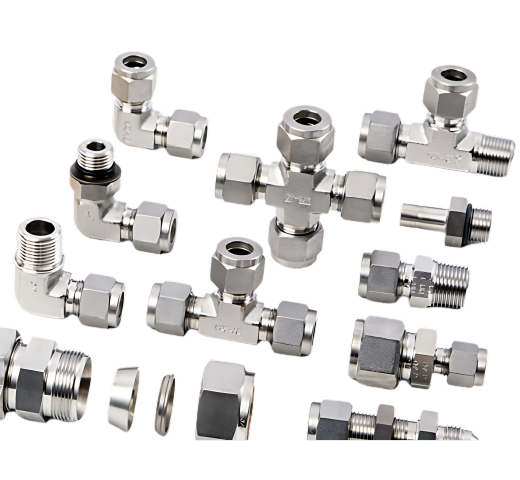

Ihara Science BI-LOK Tube Fittings

Ihara Science BI-Lok® double ferrule tube fittings provide leak free seals in process, power, and instrumentation applications and are fully heat-code traceable, self-aligning, easy to install and individually packaged in sealed protection pouches. Including superior corrosion and vibration resistant designs, from cryogenic to steam, vacuum to tubing yield pressures, BI-Lok® fittings offer multiple leak free remakes in a wide range of varying pressure and temperature operating environments.

*Stainless products are RoHS compliant.

Contact the team for more information