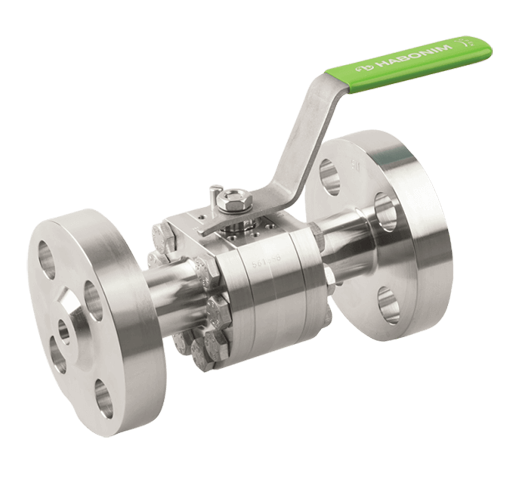

Product

ITT Habonim 28 Series High Pressure Ball Valve

The ITT Habonim high-pressure valve series is based on a floating ball valve technology, specially built for endurance and reliability with a design pressure of up to ANSI Class 2500 (414 bar / 6000 psi). As standard, the high-pressure valve series is made from forged or rolled bar material.

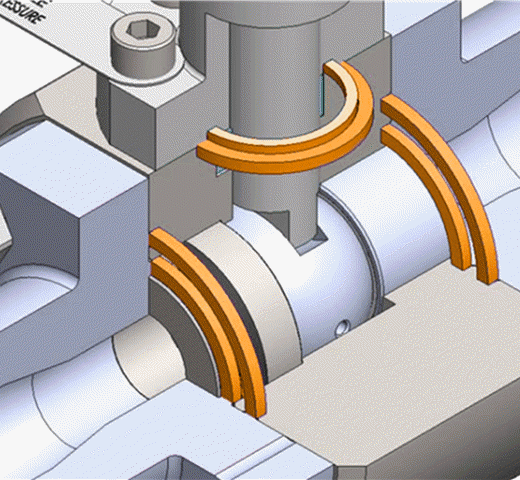

The 28 series with sizes up to and including 2″ (DN50) is capable of operation under full Class 2500 differential pressure, providing smooth and trouble-free functionality. For sizes 2½” (DN65) and above the 28 series with hybrid seats can handle differential pressure of up to 255 bar (3700 psi).