Reduce total cost of ownership with Alfa Laval LKH Prime for CIP return and dairy product handling

Many industries have been looking for a self-priming pump that meets requirements for improved energy efficiency and reduced noise levels, as well as the latest hygienic design standards. Using airscrew technology, the Alfa Laval LKH Prime sets a new standard in self-priming pump technology. This bodes well for the dairy industry, offering a sound way to realize a low cost of ownership and increased uptime.

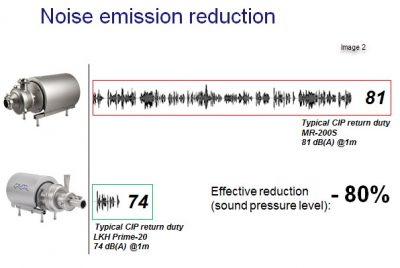

This new self-priming pump is based on the Alfa Laval LKH premium range of centrifugal pumps, which is world-renowned for hygienic design and gentle product treatment. The Alfa Laval LKH Prime is specially constructed for pumping liquids containing entrained air, making it an excellent choice as a CIP return pump. Depending on the duty point, the Alfa Laval LKH Prime is 60 to 70 per cent more energy efficient than a conventional liquid-ring pump and operates at noise levels of 74 dB(A), a full 80 per cent less than a conventional liquid-ring pump. Like the other pumps in the LKH family, the Alfa Laval LKH Prime is EHEDG certified and authorized to carry the 3-A symbol. Versatile and efficient, the Alfa Laval LKH Prime is therefore of interest to dairy owners and operators who are concerned with:

- Reducing energy consumption

- Improving the work environment

- Reducing installation costs

Reducing energy consumption

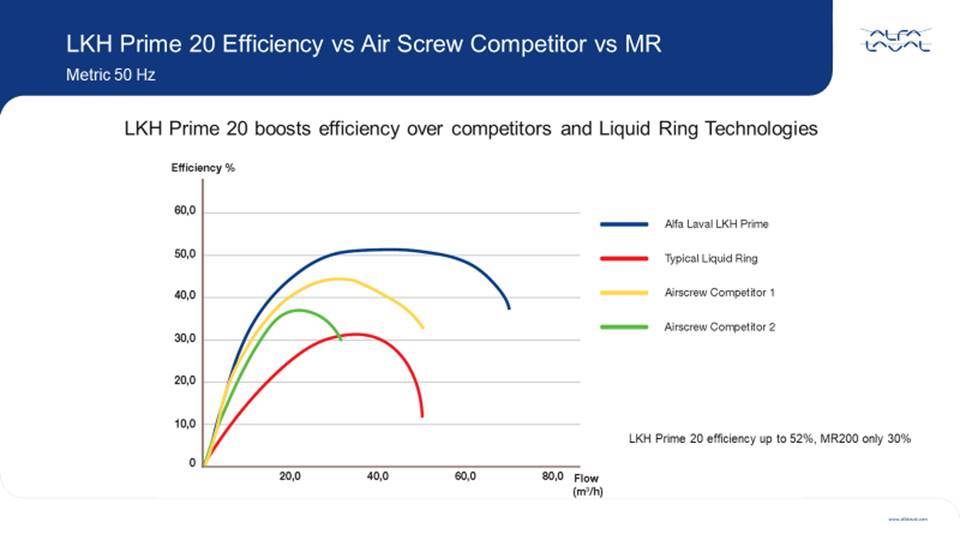

The hydraulic efficiency of the Alfa Laval LKH Prime reaches over 50% (Image 1). This means the Alfa Laval LKH Prime offers an added advantage over liquid-ring pumps, which typically reach efficiencies of approximately 30 per cent. Its high efficiency is easily attainable at a wide flow range, which translates into substantial savings no matter the duty point. Energy efficiency is important for operations, and the Alfa Laval LKH Prime does not disappoint. It can be used as a Cleaning-in-Place (CIP) return pump for several different product lines so that the Alfa Laval LKH Prime is operational for several hours a day. Its hygienic design means the pump may also be used to empty dairy product tanks, which further increases the pump’s operating hours.

Improving the work environment

The Alfa Laval LKH Prime also contributes to a better work environment. It reduces the noise emission level by up to 80 per cent compared to conventional liquid-ring pumps (Image 2). Whilst reliable, liquid-ring pumps have always posed the challenge of excessive noise. In an attempt to reduce the noise, enclosures around the liquid-ring pumps and installed devices have been built or air has been added to the CIP liquid (less air in the product means more noise from a liquid-ring pump). This makes installations with liquid-ring pumps inefficient, expensive and still very noisy. With a noise level of a mere 74dBA, the Alfa Laval LKH Prime efficiently eliminates the need for these protective measures.

Reduce capital expenditures and annual costs

Operators looking to cut initial investment costs as well as operating and maintenance costs should consider using the Alfa Laval

LKH Prime Pump (Image 4). This advanced self-priming pump is a hygienic workhorse hand-ling for CIP return duties where the liquid contains entrained air just as easily as other duties where require gentle product treatment is required.

Why use two pumps when a single Alfa Laval LKH Prime is versatile enough to do both jobs and deliver measurable savings to your plant?

As the Alfa Laval LKH Prime pump starts up, the centrifugal force generated from the rotation of the airscrew and the initial priming liquid causes the formation of a liquid ring in the pump head canister (1). This also fills the re-circulation pipe (2), thereby achieving the initial prime.

Due to the offset design, an air column is created between the airscrew hub and the liquid ring at the bottom of the canister (1). The rotating vanes of the airscrew separate the air column into air pockets, which are forced through the canister into the impeller’s suction stage.

Some of the initial priming liquid re-circulates from the casing discharge into the airscrew casing through the re-circulation pipe (2). Until all the air has been evacuated, air pockets will continue to be generated.

When the air content is just a few per cent, the air is contained as bubbles in the liquid. No air pockets are generated. Instead, the liquid/air mix passes through the canister into the impeller’s suction stage (4). Here, the pump acts as a traditional centrifugal pump, transferring the liquid through the discharge (5) at a higher velocity and pressure (image 5).

When there is no air present, the canister and re-circulation loop have no function and are filled with liquid. The liquid passes through the canister into the impeller’s suction stage. Here again, the pump acts as a traditional centrifugal pump, transferring the liquid through the discharge at a higher velocity and pressure.

Saving energy, and costs improving the work environment

In summary. Compared to traditional liquid-ring pumps, the Alfa Laval LKH Prime Pump significantly contributes to three common focus areas in modern dairy processing:

- Reducing energy consumption

- Improving working environment

- Reducing installation cost

With the further benefit of spare parts commonality with the Alfa Laval LKH pump range and operational flexibility, the Alfa Laval LKH Prime Pump is the obvious choice for pumping liquids containing entrained air.

** Above is an extract from an article by Allan Bruun, Industry Manager, Dairy, Market Unit Food, Alfa Laval **

For more information please send us a product enquiry or call us on +353 21 4510900

At ESI Tech, we provide a wide range of pumps including magdrive pumps, centrifugal pumps, vacuum pumps, single use pumps and sanitary pumps among others. Contact us for free expert advice today.