Product

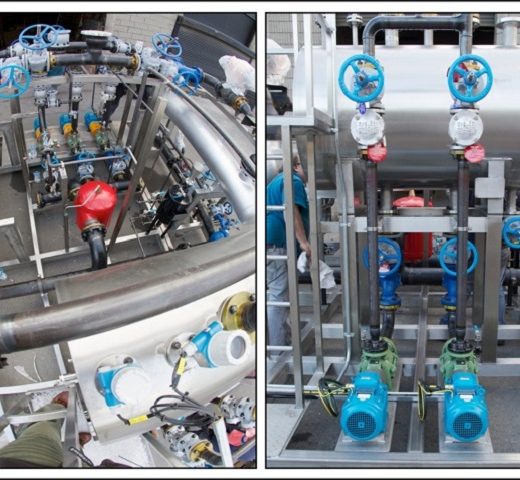

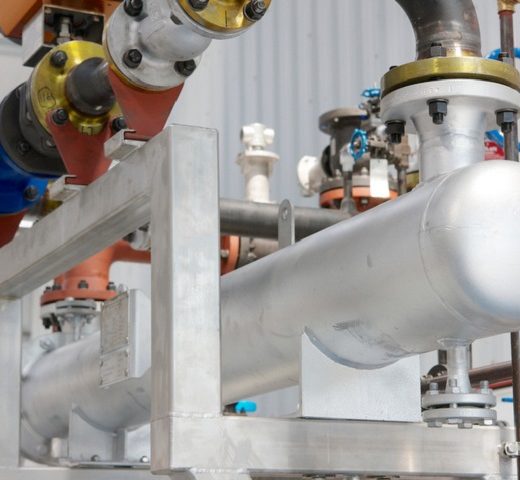

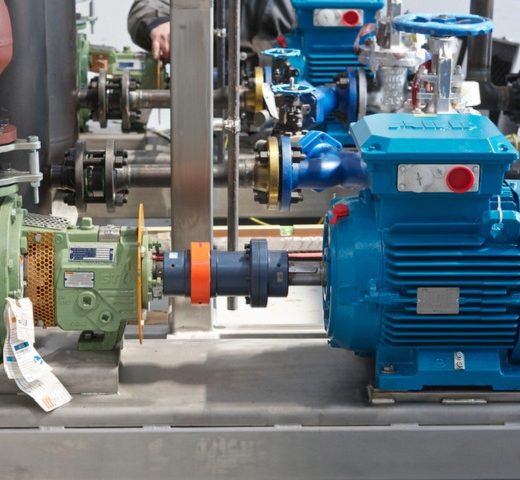

Low Pressure Hot Water Skids (LPHW)

Many systems (utility or process) require heating which can be supplied through LPHW (Low-Pressure Hot Water) depending on the heating application required, ESI Technologies can provide a single unit solution that provides the LPHW heating functionality within a single skid-mounted system.

ESI can offer the service from basic to full design including P&ID, 3D GA Drawings/Models incorporating the clients’ requests whilst giving full flexibility in meeting their demands.