Do you need to ensure actuated valves are locked-out during maintenance cleaning intervals?

Do you need to ensure actuated valves are locked-out during maintenance cleaning intervals?

During cleaning of actuated valves and when a power source is connected to the actuator there is an inherent danger that a personal injury could occur in the event a valve closed or opened accidentally.

The consequences of such an incident would be catastrophic for site and could lead to personal injury or fatality.

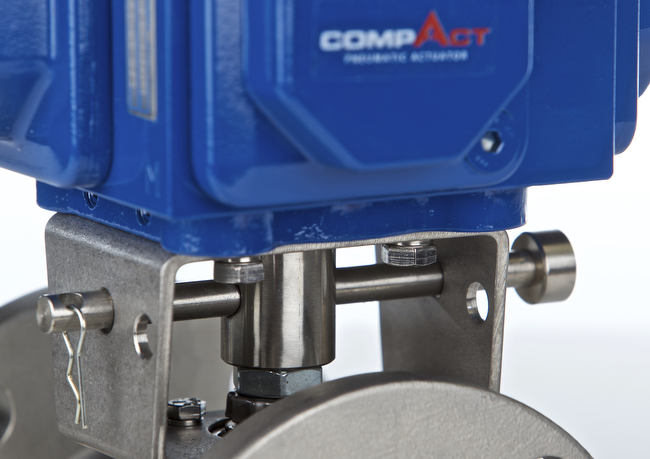

For all standard actuated valve packages ESI have designed a special oversized coupling drive and drilled a hole through it which, along with a hole drilled through the mounting bracket sitting between the valve and actuator, allows the maintenance engineer to fit a pin through the bracket. A lock can then be fitted at the end of the pin, ensuring that the valve is fully locked-out prior to any cleaning taking place.

Pin sizes are selected by bracket and coupling sizes, all materials are 316 s/s and the oversized coupling ensures that it cannot twist in the event of high torque being applied

Rob Leadbeater or Darryl Flowers on UK: +44 1633 877505; or Brian Foley or Zane Flaiani on Ireland: +353 21 451 0900; can provide more information or send us a product enquiry for more details.