Under extremely low temperatures and in the harshest of environments, Habonim’s cryogenic ball valves consistently exhibit high flow capacity, tight shut-off, energy efficiency and long service-free life

Safety

Habonim’s meticulous engineering approach and long experience in the valve industry has resulted in a unique cryogenic valve design. As standard, the Habonim cryogenic ball valve design is fire-safe ready and suitable for hazardous and non-hazardous environments

Some of the principle features of the Habonim cryogenic ball valves are:

- Efficient Heat Transfer

- Hermetix Stem Packing

- Hydrostatic testing

- Safe operation

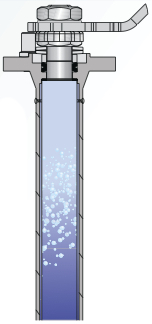

Efficient Heat Transfer:

The unique bonnet design allows only a thin layer of flow between extension ID and stem OD, resulting in optimum heat transfer and minimum energy loss along the extension.

Extended bonnet length for cold box applications can be also be provided.

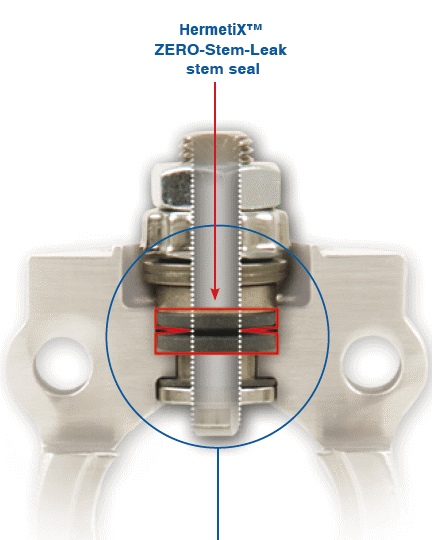

Stem Packing:

The cryogenic valve series uses a unique stem packing design patented by Habonim, the Hermetix

The unique geometry of the Hermetix ensures zero leakage and a maintenance-free product life.

The flexible X shape of the Hermetix allows a dynamic sealing arrangement in case of stem side load occurrence

Sealing is improved while increasing pressure and maintaining stem packing integrity due to relaxation of stem spring preload and erosion of soft parts

This is a great advantage over linear motion valves such as globe valves which by definition are prone to leakage and require a rigorous, time consuming maintenance regime.

Testing:

Valve parts (less ball, stem and original soft parts) are hydrostatically tested to 1.5x pressure rating

The valve is then dis-assembled and cleaned in an ultrasonic bath and degreased to ensure a high level of cleanliness. The valve is assembled in a cleanroom and 100% line tested with helium at 80psi and checked with a helium leak detector

After testing, the valve ends are capped and the valves are individually packed in a hermetically sealed polyethylene bag, ensuring valve integrity up to the point of installation

Cryogenic testing: in certain cases, a cryogenic valve test at operational temperatures can be performed

Safe operation:

The cryogenic valve stem is designed to prevent the stem being ejected when the operating or sealing devices are removed

The tongue and groove design is used in all fire-safe valves and is now also implemented in the cryogenic valve series.

This unique labyrinth design provides zero leakage to the atmosphere. It is intended to allow full compression of the expanded graphite body seal and accurate alignment of the body and ends.

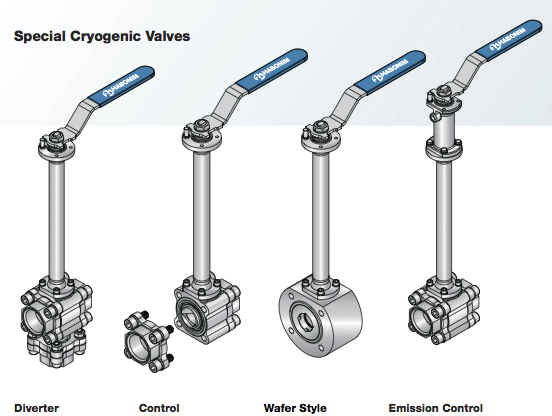

Special cryogenic ball valves are also available in the following configurations:

- Diverter. Diverting cryogenic valves are available in bottom or side entry. The valves have balls with T or L port configurations

- Control. The ProfiX control valves are available for cryogenic applications, giving the advantage of precise control with tight shut-off

- Wafer Style. Habonim wafer style cryogenic valves offer an ideal economic solution for exotic materials

- Emission Control. Cryogenic valves are available with a Fugitive Emission Bonnet, offering a high integrity solution for stem leakage of toxic gases or for high cycle applications

Contact Brian Foley at ESI Technologies on either +44 1633 877505 or +353 21 4510900 or use the contact form for further information on cryogenic ball valves for LNG, or other applications