MENUMENU

Hydrogen has a light atomic weight and molecule structure turning hydrogen-use equipment sealing into a challenge that requires special designs, mechanisms, and expertise. Hydrogen is highly combustible and flammable making leakage prevention an essence for the safety and integrity of systems and materials selection should consider hydrogen effects as Hydrogen Embrittlement (HE).

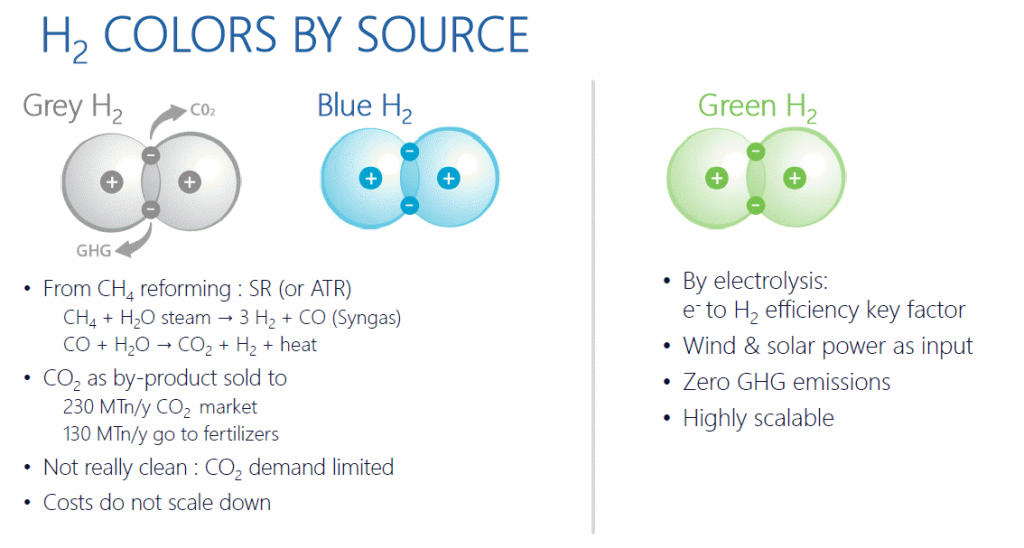

Grey hydrogen is split natural gas using SMR (Steam Methane Reforming) or ATR (Auto Thermal Reforming) into Hydrogen and CO2. The CO2 is not captured and is released into the atmosphere.

Blue hydrogen is produced by splitting natural gas using SMR or ATR. It produces hydrogen and CO2. The CO2 is captured and stored through a process called CCUS (Carbon Capture Usage and Storage).

Green hydrogen is produced by splitting water by electrolysis. This produces hydrogen and oxygen. The oxygen is released into the atmosphere with no negative impact.

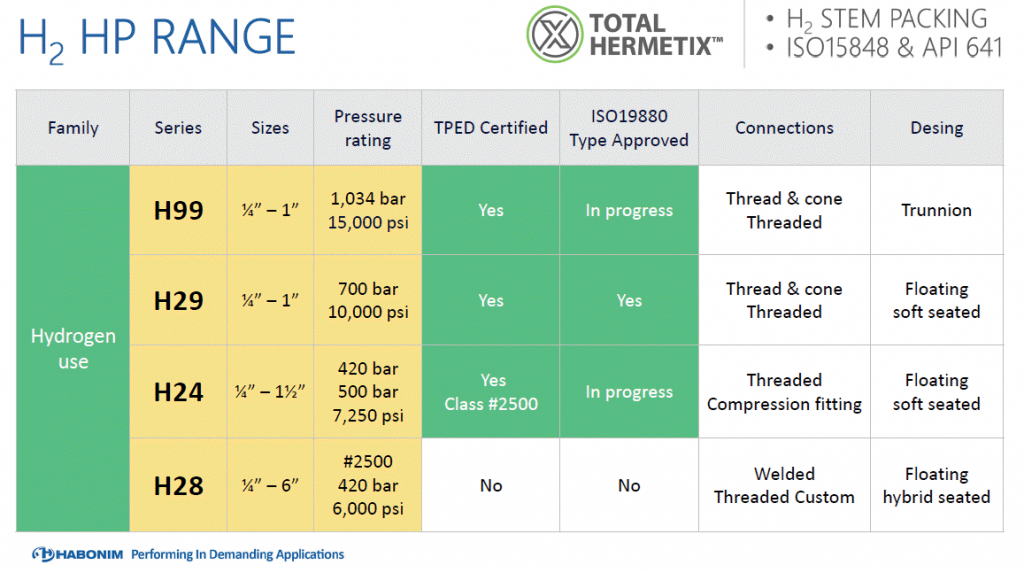

ITT Habonim offers a full range of ball valves for hydrogen use, based on the legacy product families to cover low to very-high pressures for shut-off and control use. This encompasses regular two-way, multiport, double block & bleed and custom-made designs including both manual and actuated valve packages.

Design

ITT Habonim Hydrogen-use ball valves incorporate some design elements to best accommodate the hydrogen media:

Double Stem Sealing

Habonim HermetiX patented stem seal is used with additional O-ring sealing.

The HermetiX polymeric, non-graphite stem seal design is certified for ISO15848-1 and API641 fugitive emission prevention standards, tested with Helium.

An additional O-ring stem seal is added as an additional sealing point. This design has been successfully tested for 100,000 open/close cycles under pressure without any maintenance or seal replacements and has performed well in demanding hydrogen applications for decades.

Hydrogen-use material compatibility

All materials used for the valve constructions are specified for safe use with hydrogen media. Metallic materials to be used in the valves are selected to withstand the hydrogen embrittlement effects and are compatible with hydrogen use.