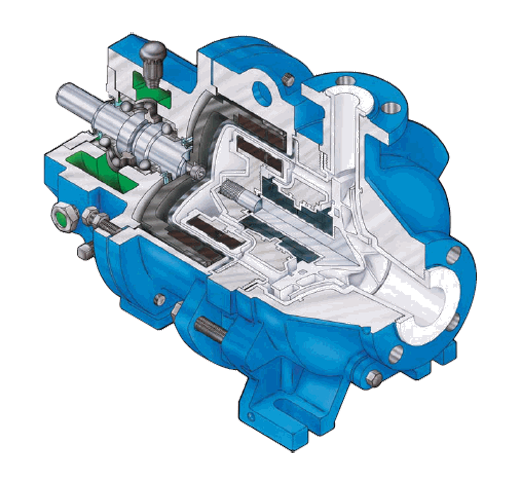

Design Features

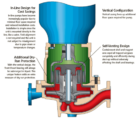

Close-Coupled Design

Arrangement eliminates the need to perform pump/motor alignment. Single piece, dual bolt circle adapter accommodates all motor sizes for maximum application flexibility.

Rare Earth Magnets

High-strength neodymium iron, provide high torque and hard-start capability without slip. Drive is synchronous.

Containment Shell

ETFE lining with glass reinforced vinyl ester backing. Rugged design with burst pressure greater than 500 PSI. Non-metallic construction provides efficiencies with the same as sealed ANSI pumps. (30% higher efficiencies than metal seal less pumps).

Rigid Casing Feet

Reduce the effect of pipe loads on pump and motor shaft alignment.

Radial Bearing With PTFE Spacer

A two-piece design with a PTFE spacer allows bearings to self-align under load. Independent movement maximizes bearing life. Carbon bearing construction standard; silicon carbide and Dryguard™ optional.

Clamping Ring

Pressure retaining ductile iron for safety.

Fully confined O-Ring

Sealed to the casing for zero leakage. Acid-resistant Viton standard other materials available

Casing Drain

Allows complete draining of fluid from the pump for system maintenance. Blind flange and gasket ensure leak-free seal for safety.

Bearing Lubrication

Generous passageways in the magnet and bearing circuit result in the smallest possible pressure drop across the bearings. This maximizes the flow rate and the pressure in the critical bearing area to prevent vaporization and loss of hydraulic bearing support. Unique vane geometry in the containment shell coupled with dynamic grooves in the bearings prevents solids from getting trapped and accumulating in the circulation path. Can pass 5% (by weight) soft solids up to 160 microns. Other pump designs will “choke” on small solids due to tight clearances with multiple static flow paths.

ANSI Dimensions

Allows easy retrofit of problem ANSI pumps.

ETFE Construction

Provides superior corrosion resistance; inert to most chemicals. Tough material for superior solids handling/abrasion resistance (same or better than 316 SS).

ETFE Lining with Ductile Iron Casing

One-piece solid casing lined with minimum 1/8 inch (3 mm) ETFE. Rotolining process assures mechanical integrity of lining.

One-Piece Enclosed Impeller

Minimizes axial thrust for extended thrust bearing life. Unlike two-piece designs, one-piece construction eliminates the possibility of front shroud failure.

Solid Stationary Shaft

Pure sintered silicon carbide construction eliminates shaft deflection. A fully supported stationary design maximizes radial bearing life. Straight geometry eliminates stress concentrations and the possibility of failure during pump operation.

Bearing Spider

Fully supports Silicon Carbide shaft for maximum shaft rigidity. Protects the end of the Silicon Carbide shaft from damage. Smooth hydraulic flow path into the eye of the impeller, equal to that of a standard ANSI pump. Rounded spider hub and spider supports (flow straighteners) reduce turbulence and pre-rotation for better hydraulic stability.

Options

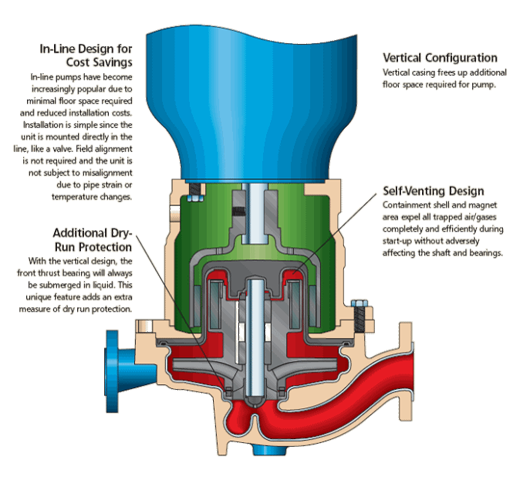

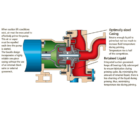

V 3298 In-Line Design for Cost Savings

In-Line pumps have become increasingly popular due to minimal floor space required and reduced installation costs. Installation is simple since the unit is mounted directly in the line, like a valve. Field alignment is not required and the unit is not subject to misalignment due to pipe strain or temperature changes.

Vertical Configuration

Vertical casing frees up additional floor space required for the pump.

Additional Dry-Run Protection

With the vertical design, the front thrust bearing will always be submerged in liquid. This unique feature adds an extra measure of dry run protection.

Self-Venting Design

The containment shell and magnet area expel all trapped air/gases completely and efficiently during start-up without adversely affecting the shaft and bearings.

Parts Interchangeability

All components are fully interchangeable with 3298 and SP 3298, except the casing. Reduces spare parts inventory requirements.

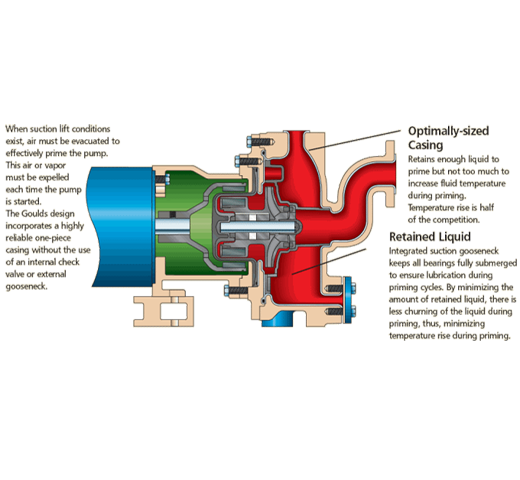

SP 3298 for Self-Priming Applications

When suction lift conditions exist, air must be evacuated to effectively prime the pump. This air or vapour must be expelled each time the pump is started. The Goulds design incorporates a highly reliable one-piece casing without the use of an internal check valve or external gooseneck.

One-Piece Casing without Check Valve

Provides reliable priming in all conditions. Eliminates the additional gooseneck component found on other brands. Retains the proper amount of liquid in the casing to prime without the use of a troublesome check valve. Check valves are commonly used to retain liquid in the casing to assist in priming on successive uses. However, these check valves wear quickly and contribute additional losses on the suction side due to induced drag. Goulds has eliminated the check valve and the SP 3298 outperforms our competition in priming times.

Parts Interchangeability

All components are fully interchangeable with 3298 and V 3298, except the casing, volute insert, and backplate. Reduces spare parts inventory requirements.