Product

Saunders P345 Pneumatic Actuator

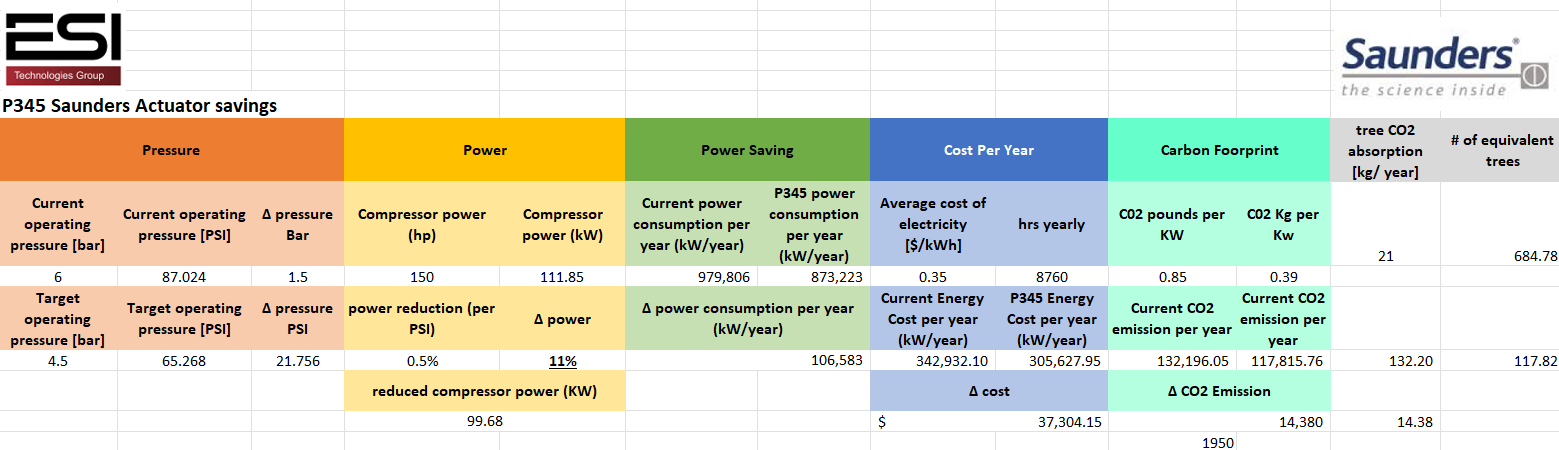

The Saunders® P345 Polymer Pneumatic Actuator is designed to reduce operating pressure requirements to 4.5 bar, which can reduce your carbon footprint and energy costs by 11% (see below for details). The lightweight piston-type pneumatic actuator has been developed to deliver sustainable performance for Sterile Biopharmaceutical applications. The piston-type actuator permits remote operation of the valve, either as an alternative to manual operation or as an integral part of a control system.

The P345 housing is manufactured from a hybrid construction of polished 316 Stainless Steel and glass-filled Polyamide, producing a robust design, a clean OD profile, and an attractive appearance. It can withstand typical industry washdown regimes.