Product

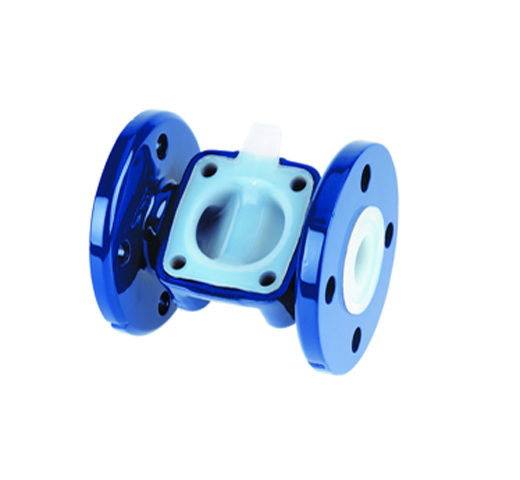

Saunders Industrial Diaphragm Valves (IDV)

The Saunders® Industrial Diaphragm Valves, first developed more than seventy years ago, has evolved to handle more fluids, gases, solids, and powder than any other type of valve. A wide choice of materials is available and a flexible range of operating methods has been developed to satisfy the needs of most industrial applications.

Extended life, reliability, safety and ease of use, combined with an essentially simple design, facilitate low maintenance and minimal running costs

ESI Technologies Group are pleased to announce its appointment as the Official Channel Partner and Distributor for Crane “Saunders” HC4 and IDV products in Ireland.