Features of Saunders Aseptic Diaphragm Valve Body

The standard 2-way valve body is the basic building block of diaphragm valve technology. CRANE Chem-Pharma, Saunders® 2-way forged bodies are manufactured from wrought 316L/1.4435 stainless steel bar with the additional requirement of controlled sulphur per ASME BPE Standard.

The forging process results in a homogeneous surface that helps to eliminate porosity, inclusions, or shrinkage cavities. This surface is an ideal substrate for the high levels of mechanical and electropolished surfaces demanded by the clean processing industries to maintain sterility and optimize cleaning processes. CRANE Chem-Pharma, Saunders® forged bodies are manufactured to achieve low ferrite levels of less than 0.5% maximum. This reduces the potential for migration of oxides through a high-purity water system.

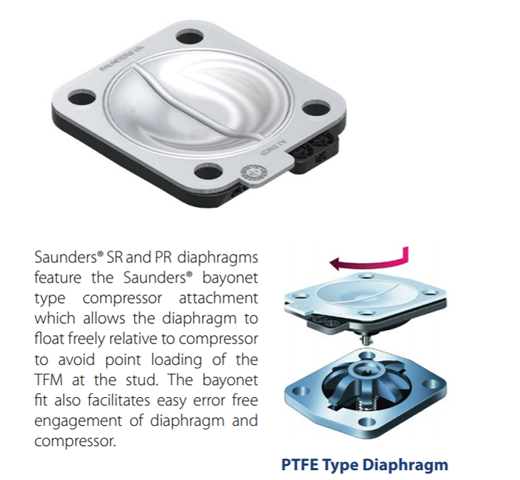

Diaphragms for Saunders HC4 Valves

The diaphragm is a critical performance element in diaphragm valve design and must be engineered to perform both as a static seal at the perimeter of the body flange to safeguard the process from the external environment and as a dynamic seal to ensure positive closure against line media. In service, the diaphragm is subjected to high mechanical stresses as process fluid works against the diaphragm and must provide safe, secure and repeatable processing for a wide range of process and utility applications.

Saunders® develops compounds and manufactures all elastomer and PTFE diaphragms in-house from raw ingredients and has front-to-back ownership of all phases of diaphragm development and manufacture. This includes the sintering and coining of 2 piece PTFE diaphragms as well as the compounding, calendering and compression moulding of elastomer diaphragms.

In developing compounds for biopharma applications, Saunders® endeavours to maximize critical performance characteristics unique to the life science industries while complying with FDA, USP and all global regulatory requirements. These factors include process compatibility, extractable level, temperature and nature of cleaning regimes (CIP & SIP) and system passivation.

Saunders® HC4 diaphragms are fully compliant and tested to global standards including FDA, USP Class V & VI, and TSE/BSE. In addition, to assist with the demands of validation and to provide the highest level of security, reliability and regulatory compliance, Saunders® provide full batch traceability for all grades of HC4 aseptic diaphragms.

Saunders Custom Solutions

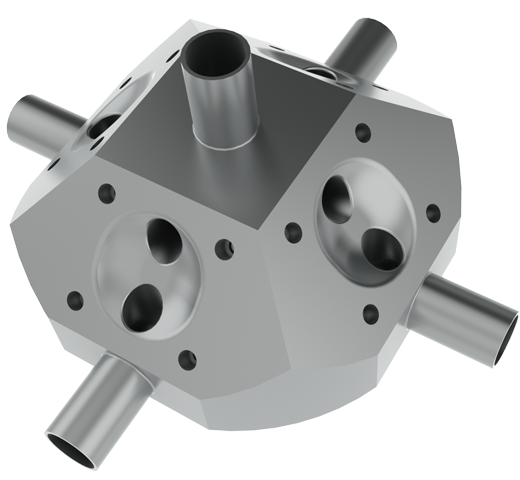

Saunders Bio Block

Saunders® Bio Block bodies are a unique platform of custom full-stop designs. These innovative Machined Block solutions may be driven by process, space constraints, system design, piping challenges, orientation requirements or regulatory issues. We work closely with our customers to design and develop fast-track menus of Bio Block solutions to meet the unique challenges of Life Science applications.

Bio-Block Categories Machined From Solid Options

- Zero-static Weir: Tee fitting and weir combined

- Serial Weir: Two weirs sharing a common chamber

- Multiple Weir: Three or more weirs with a common chamber

- Tank Weir: Weir integrated into the tank bottom

- Compound Bio-Block: Combination of Bio-Block types into one assembly

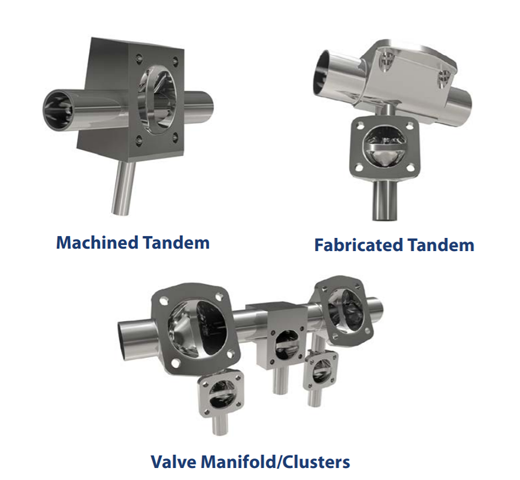

Tandem Valves (Sterile Access Valves)

Tandem valves are designed to optimize drain-ability and meet process design requirements for minimum dead legs. The main valve is ported and a second access valve is welded to the main valve to create a tandem cluster.

Machined Tandem Valves

The Machined Tandem is a variation of the Serial Weir family. This machined from solid Tandem Valve type offers several advantages over the welded tandem:

- Fabricated Tandem

- Increased security – no internal fabrication welds

- Reduced dead leg – depending on the orientation

- Greater structural integrity

Custom Valve Solutions

Custom valve types may be welded tandem valve assemblies, machined from solid block types or manifolds that incorporate both technologies.

Valve Manifold / Clusters

Configuration of optimum process fabrication presents system designers with an ongoing challenge. Minimum space envelope reduced hold-up areas, reduced cost, and facilitating ease of installation are all key considerations.

Top works

Top works including both actuation & manual bonnets.

Saunders-VUE portfolio offers industry-leading automation technology that adds intelligence to a diaphragm valve, delivering savings to the customer.