Product Benefits

No Impingement

Boundary Layer – a boundary layer of fluid molecules collects, and rotates with the discs. This creates a natural, protective buffer that separates the pump from the fluid.

Non-Pulsating / Laminar Flow

Viscous Drag – through viscous drag, the fluid is pulled through the pump without impingement. The boundary layer attracts and drags successive layers of fluid molecules into layered flows of parallel streams. This is the simple principle of viscous drag and in the Disc Pump, it is a powerful dynamic force that “pulls” the fluid through the pump in a smooth laminar, non-turbulent flow.

Rotary discs provide non-impingement pumping — that means less wear and greater protection for your product.

Features

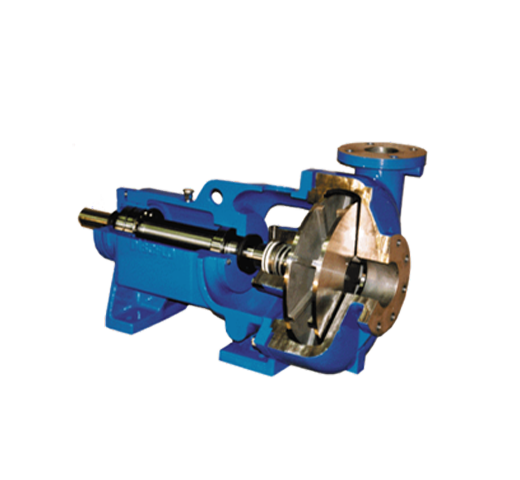

The DiscPac

It is the Discpac that makes the Disc pump so revolutionary. All other pumps use some type of impingement device – relying on the force of impact to push the fluid through the pump. This impact is hard on shear-sensitive products, and it creates pulsation that wears the pump and damages piping. The non-impingement operation of the Disc pump makes it different from any other pump on the market today.

The Disc pump uses a series of parallel discs called the Discpac. As the discs rotate, they create a boundary layer and viscous drag force that pulls the product smoothly into the pump. There is no destructive impact with an impingement device.

Versatility

The Discpac can be designed for the gentlest possible pumping of shear-sensitive solids and gaseous froths. At the same time, it can handle aggressive slurries with heavy viscosities and highly abrasive solids content.

The Disc Pump can be designed with over-size suction and discharge.

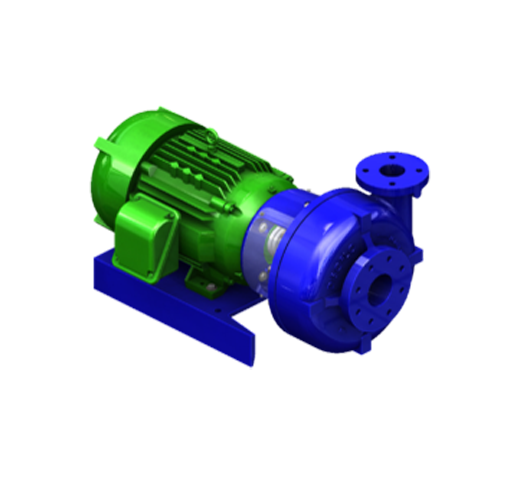

A wide variety of metal and non-metallic materials are available for the pump and its components and over a dozen configurations including API-610 and ANSI 2000 using Disc technology.

Cutting Edge Technology & Design Excellence

No Reduced Performance Efficiencies

No close tolerances and no impingement device mean no metal-to-metal component wear.

Low NSPH Requirements

Laminar flow means low NPSH! It prevents reduction in head and capacity and further reduces noise and vibration. The NPSHr is about half to one-third of a centrifugal pump in the same service conditions.

Less Wear – No Pump Vibration

Smooth flow through the pump saves wear and tear on the entire pump system (and your product).

It also eliminates pump vibration and excessive noise.

Open Design – Virtually Clog-free

The straightforward design of the Disc pump conserves space and makes assembly and disassembly quick and easy. The open design prevents clogging. Optional pull-out back.

Options

Customised Sealing Options

Sealing

Wide range of sealing arrangements is available to meet service conditions.

Seal chambers

An optimum seal design for a wide range of sealing options, including tapered and oversize bores.

Heavy Duty Bearings and Large Oil Sump

Labyrinth Oil Seals

This type of oil seal provides maximum chemical resistance with Teflon*. Prevents premature bearing failure due to oil loss and contamination.

Lubricant

Users can easily convert from standard oil to oil mist or grease if desired.

Heavy duty shaft and bearings

Minimal shaft deflection at seal faces. Average bearing life of 10 years even in tough operating environments.