Product Benefits

Space saving & fast acting actuators

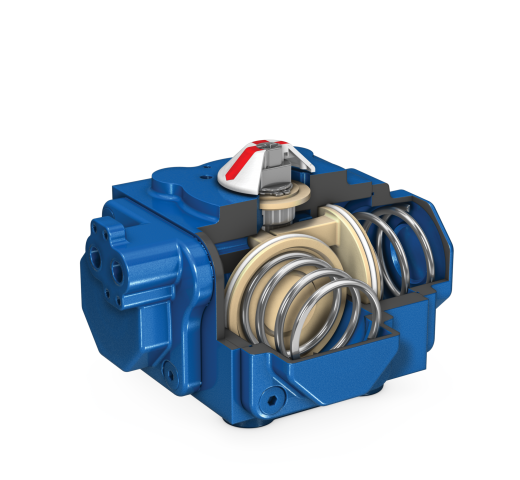

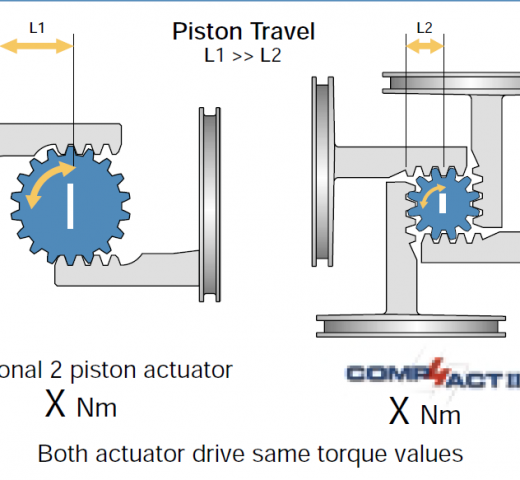

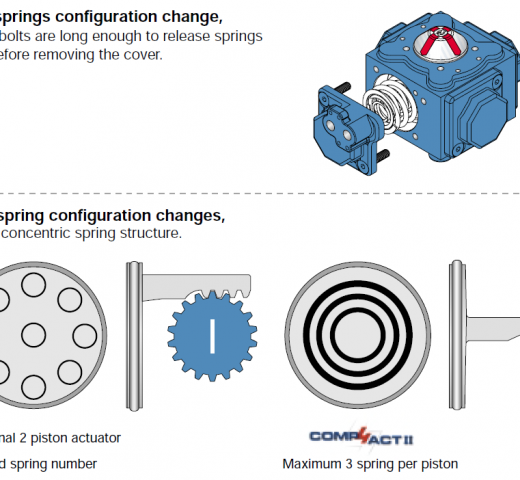

The COMPACT™ actuator has four small cylinders, one located on each of the four sides of the cube. The smaller pinion and shorter travel distance of the pistons in the COMPACT ™ require less air pressure than a larger double-piston actuator to produce the same torque output. The result is faster response times for emergency shutdown, lower air pressure for operation and reduced maintenance.

Configurations

The COMPACT can be configured for either spring return or double-action operation. In both cases, the air supply to drive the pistons flows into Port A of the NAMUR cover. Port A is connected to the centre chamber, and Port B is connected to the four outside chambers. See brochure for more details

Ordering codes include C15, C20, C25, C30, C35, C45, C60 & C75

NAMUR & ISO interface

An extensive range of accessories such as solenoids, positioners and limit switches are available for direct mounting to the COMPACT actuators. Any accessory whose connections comply with ISO 5211 and VDI/VDE 3845 (NAMUR) mounting can be connected to the actuator.

Technical Data

The COMPACT has four small cylinders, each located on one of the four sides of the cube. The smaller pinion and shorter travel distance of the pistons in the COMPACT require less air pressure than a larger double-piston actuator to produce the same torque output. The end result is faster response times for emergency shutdown, lower air pressure for operation and reduced maintenance.

- Lightweight & small volume

- Balanced forces

- Less wear

- Superior corrosion resistance

- Less air consumption

- Fast action

- Single-acting (spring return) and double-acting configurations

- High efficiency

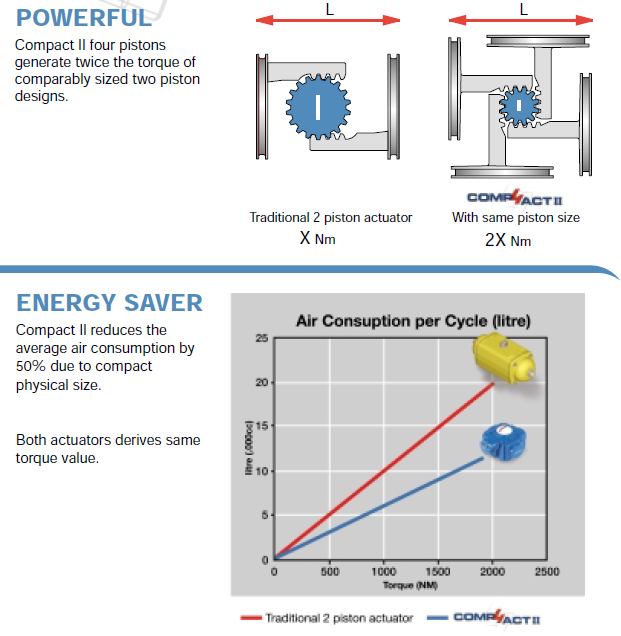

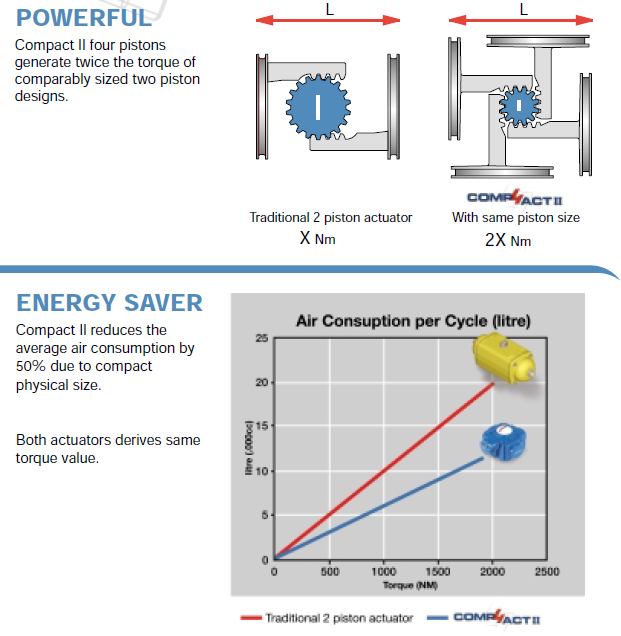

Energy Saving

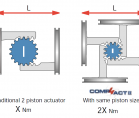

The Compact II reduces the average air consumption by up to 50% due to its compact physical size, reducing energy costs.

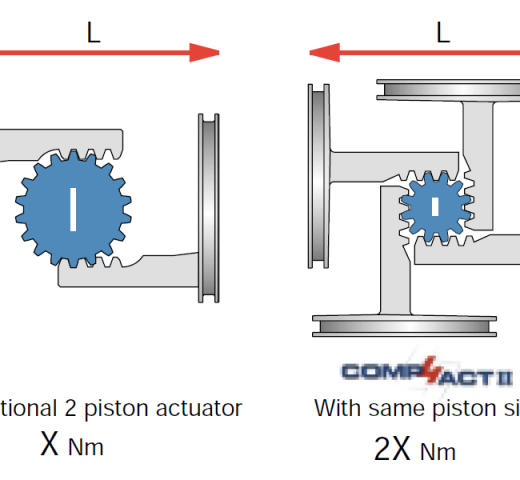

Based on patented 4-piston technology the Compact II generates twice the torque of comparably sized two-piston rack and pinion designs.

ITT Habonim’s Compact II actuator range has ATEX IIC certification and is being used in Hydrogen projects globally.